The conditions for the existence of methane-producing bacteria are artificially created and maintained in the reactor of a biogas plant. In a natural environment, organic matter decomposes for years, even thousands of years. In biogas reactors, decomposition takes from several days to several months.

Methane-producing bacteria are present in animal manure. Animal manure also serves as a bacterial seed for biogas plants.

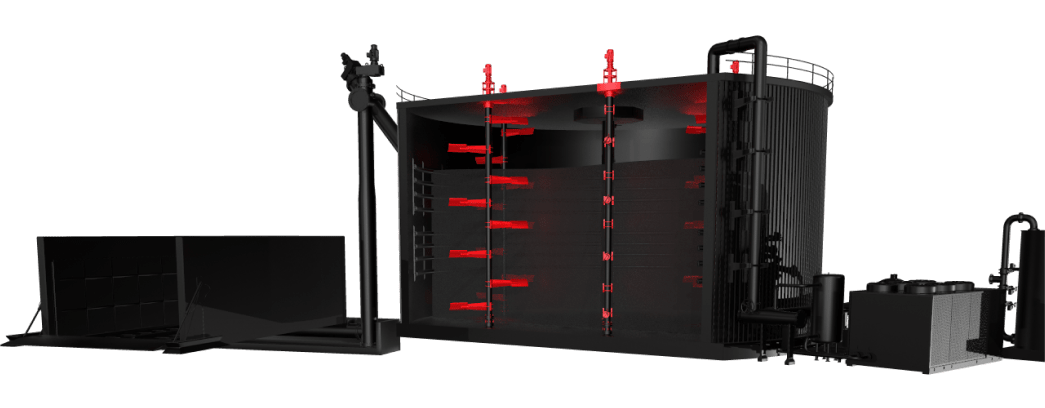

Biogas plants are designed for the production of biogas from the waste produced by the food industry and agriculture, as well as from solid household waste and the silage of specially grown crops. A biogas plant consists of screw-feed loaders, a grinder, pumps, a reactor, inclined and submersible mixers, a gas holder, a desulphurization system, a biogas chiller, a compressor, a spent substrate separator, a torch, a gas analyzer, and a generator. A biogas reactor is also called a biogas fermenter, biogas digester, or anaerobic reactor.

Main sections of a biogas plant:

Reactor

The reactor is the most important element of a biogas plant. It is here with the help of anaerobic bacteria that fermentation and the release of biogas occur. The reactor is a container constructed of steel or reinforced concrete.

Mixer

A mixer is a device for stirring the substrate and breaking the crust which forms. There are submersible, inclined, horizontal and vertical mixers. Mixer blades are positioned in such a way as to create ascending and descending flows for heat and mass transfer.

Loader

The loader is a device for dosing and feeding solid raw materials to the reactor. There are loaders with a scraper floor, moving bottom floor, and screw feed. For a high-quality loader, the walls are made of wear-resistant material.

Augers

A screw-feed loader is a device for transporting solid raw materials from the loader to the reactor. The screw material is wear-resistant high-quality stainless steel. A good auger has guides inside the outer casing, and the shells are collapsible to remove foreign objects.

Heating-cooling

In a biogas reactor for the life of the bacteria, the temperature should be maintained between 38° to 55° C, and both heating and cooling may be required. Heating and cooling can be carried out using pipes inside the reactor or in an external heat exchanger.

Biogas Chiller

A biogas chiller is equipment for simultaneously cooling biogas and for removing moisture (dehydration).

Desulfurization

The desulfurization system utilizes an activated charcoal filter. The filter reduces the level of hydrogen sulfide from 1,200 ppm to 20 ppm. As a result of this biogas treatment, the generator’s lifespan may increase by a factor of 5.

Biogas Technologies

We offer the most reliable and modern technologies for various industries